EPOXY COATINGS

/

It is a low volatile organic content paint with a high solid content. It is a modified epoxy

coating that gives long term protection with high resistance properties and is ideal for use

in harsh marine and industrial environments where there is no compromise on quality.

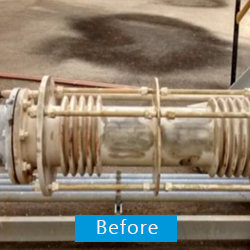

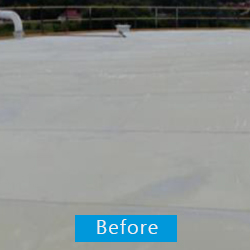

CORROSION RESISTANT COATINGS Need the best anti-corrosion coating for your industrial

equipment? Rely on Aqua ST-03. It offers extreme protection against oxidation, moisture,

salt spray and much more. Due to its anti-corrosion properties, Aqua ST-03 ensures long

lifespan for your industrial equipment. These corrosion resistant coatings are ideal for

metal surfaces including steel. While choosing the best coating for your equipment, you need

to make sure if it is environmentally compatible or not. Aqua ST-03 is not only Eco-friendly

but also a high performance coating. This type of anti-corrosion coating also fights

friction, resists chemical exposure failures, minimizes wear and tear, and helps Equipments

to maintain their tolerance.

At Flosil-BET, we ensure that our high-quality marine and protection coating system do not

let your equipment degrade away. Our coatings provide immediate protection for all your

industrial equipment. It's easy to apply and offers long term resistant against any form of

corrosion. Let us help you with long term corrosion through this short term expense of only

applying the best marine and protection coating system.

Our industrial marine coating system looks after assets continuity and preservation. In line

with our expertise and experience, we have developed and patented products that meet such

critical demands and conditions. Our priority is providing protection for all your

industrial equipment regardless of its age. We extend our coating services for new and old

equipment.

Epoxy coating service offers:

- Excellent Adhesion

- No Shrinkage

- Anti Static

- High Resistance to Abrasion & Impact

- High Resistance to Acids, Alkalis & Solvents

At Flosil-BET, we ensure that our industrial marine coating system is of top quality. We

follow responsible and environmentally friendly processes when it comes to suggesting

premium quality industrial marine coating systems. We enhance the quality of our product to

ensure that your equipment is safe and sound against demanding conditions. Our products

undergo rigorous testing to ensure that it serves as high-performance coatings. The quality

is approved by a wide range of industry bodies and individual customers.

WE PROVIDE BEST EPOXY COATING SERVICES

|

|

Acid*

|

Alkali

|

Solvent

|

Sea Water

|

Fresh Water

|

|

Spillage

|

C

|

A

|

B

|

A

|

A

|

|

Fume

|

B

|

A

|

A

|

A

|

A

|

|

Immersion

|

NR

|

NR

|

X

|

A

|

A

|

NR: Not Recommended, X: Poor C: Fair, B: Good, A: Very Good

*Exceptional Performance towards acids like H₂SO₄, HNO₃ etc…